Would do you care to have some 3D-printed snacks with your evening tea? Or how about a piece of chocolate in butterfly-shape just off the printing machine? The Thanjavur-based Indian Institute of Food Processing Technology (IIFPT) may soon be able to deliver such personalised food products using print-and-eat technology.

Researchers at the IIFPT, an autonomous Research and Development institution under the Ministry of Food Processing, have been perfecting 3D printing technology for a variety of nutritious and personalised food products using the concept of additive manufacturing.

In recent years, 3D printing — a technique involving layer by layer fabrication of foods — has become popular as it makes it possible to customise foods as per individual preferences. With changing lifestyles, consumer attitude towards food is changing drastically in terms of preferences in taste, eating experience, nutrition, cost and convenience.

More importantly, unlike conventional cooking, 3D printing makes it possible to come up with innovative food products using raw materials that traditionally do not go together. Many advanced countries are already using the technique to prepare gourmet food.

With alternative foods

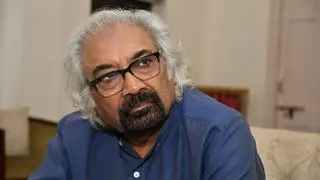

Even though a few groups, including some in industries, have been working on 3D printing technologies for food products, the institute has been researching food products that could be made available to Indian industry partners. “We have been publishing such studies since September last year,” said IIFPT Director, C Anandharamakrishnan.

The institute has been developing 3D printing technologies using various types of foodgrains or alternative foods — millet, pulses, cereals, eggs, etc.

IIFPT scientists, led by Anandharamakrishnan, in a paper just published online in the Journal of Food Processing , reported a novel 3D printing process to make fibre-enriched snacks from button mushrooms. According to the scientists, it was for the first time that the “printability” of mushrooms was reported.

“3D printing offers a good level of customisation and personalisation in terms of shape, appearance and nutrition. We foresee a long way ahead, but these research works will provide valuable insights for all future works on food 3D printing,” said Anandharamakrishnan.

But how costly would be such products? “I cannot comment on the cost at the moment, what we now have is lab-scale food 3D printers. In the long run, we can expect multi-head food 3D printers with enhanced production capacities and optimised process costs,” he said.

Biodegradable packaging

Anandharamakrishnan, however, said he doesn’t view 3D food printing as a competitor to food processing methods conventionally used, but something that supplements these processes. But it can offer high levels of customisation/personalisation, reduced processing steps, simplified supply chains, and open up global markets for Indian food products.

Another interesting application being experimented by the IIFPT scientists is developing biodegradable designer packaging cases from agro-processing waste. They have already developed a technique for 3D printing packaging material from rice husk.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.