India would be able to develop globally competitive steel making capabilities by achieving self sufficiency through backward and forward integration. This would require policy support not just to stimulate domestic demand but also to create a level playing field and, in turn, attract investments into the sector.

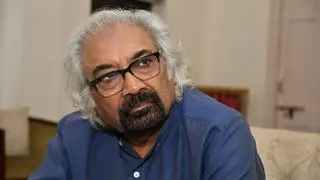

According to Sajjan Jindal, Chairman and MD, JSW Steel Ltd, such globally competitive steel making capabilities can be achieved through a few simple yet assertive steps that would also ensure sustainable growth of the Indian steel industry.

Raw material security

Apart from policy support, there needs to be security on the raw material front. “Raw material security, especially that of coking coal is key, because currently the only commercially viable way of producing steel from iron ore is by using fossil fuel such as coking coal as reducing agents. We also need to reduce dependence on coking coal from few sources such as Australia, Indonesia, US and Canada. The government has taken some focused measures under the National Steel Policy to mitigate the risk of import dependence by facilitating acquisition of overseas assets and by way exploring alternative reliable and cheaper supplies,” he said while speaking at the Minerals, Mining and Metals e-conclave organised by the Bengal Chamber of Commerce and Industry here on Friday.

India has still a long way to go in making the steel industry self sufficient. While more than a $1 trillion is set aside for India’s infrastructure, the country’s path to being recognised as a global economic powerhouse was paved in steel. India would also play a strong new role as the “factory of the world”.

“As the world pursues alternatives to China as its global factory, we are the frontrunners in replacing this East Asian giant given our skilled manpower accompanied by our abundant natural resources and access to quality raw material. This new role for the country in the global supply chain will not only push the required industrialisation but also accelerate economic growth for our country,” he said.

The government has set a target of increasing the share of manufacturing sector to 25 per cent of GDP by 2025 and to achieve 300 million tonne per annum of steel production by 2030. This would call for a multi-fold growth in steel production. According to him, while this may sound ambitious, it is not unattainable.

Steel as an industry is at an inflection point driven by a favourable shift in global supply and demand as well as a large local appetite thus ensuring sustainable growth. “I also have no doubt that the steel industry will be able to match if not exceed the expectation set for its contribution to Indian GDP due to the investments in capacity addition, innovation and introduction of cost efficient green technologies,” he added.

Achieving COP-26 goals

Steel industry, which is one of the biggest contributors to green house gas globally, would have a crucial role to play in achieving the net zero target, which India has talked about in COP-26.

While steel industry accounts for 0.7 per cent of world’s economic output, the industry contributes 7 per cent towards global emissions. This needs to change and has to change fast.“Curtailing carbon emission will require major upgradation at steel mills and the initiative has to be taken at the industry as well as the policy level. We will indeed need a new transformative approach in doing this,” he pointed out. While the transition period may involve high initial capital cost and operational cost, proactive government support through well designed policy will ensure that the industry is not discouraged from making this transition, he added.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.