Intech Additive Solutions (formerly known as Intech DMLS Pvt Ltd), provider of metal additive manufacturing in India, said it has designed, developed and delivered iFusion series of metal 3D printers for the Indian market.

Delivered under the ‘Make in India’ initiative, the iFusion SF1 and the iFusion LFMulti were designed and built at Intech Additive Solutions’ facility in Bengaluru.

Intech Additive Solutions is a pioneer in the metal additive manufacturing providing end-to-end solutions starting from concept design to fully functional production parts for various industries such as aerospace, automotive, general engineering and medical market segments.

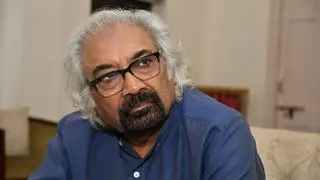

“The iFusion series of Metal 3D Printers, based on the Selective Laser Melting technology and are designed for high precision, stability, reliability and to deliver unmatched performance with higher build rates,” said Sridhar Balaram, MD & CEO.

“These cost-effective machines are part of Intech’s 3D eco system with softwares bundled in for machine parameter optimization and build process being sold as a package. The overall target of Intech is to reduce the cost of acquisition, cost of operations and first time right with a quick go to market.”

The iFusion SF1 is a smaller format machine dedicated to R&D laboratories, universities, institutions and academies. The iFusion LFMulti is a large format machine with extensive features designed for the industrial use.

“These machines are a culmination of more than 30,000 manhours of research, development and innovation spread over the past 36 months. We have 3D printed more than 800 parts for variety of industries in different materials. Along with our in-house developed Software AMOptoMet and the upcoming AMBuilder we aim to create a full-fledged ecosystem for Additive Manufacturing fuelling the industrialisation of AM in India,” added Balaram.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.