When Chittaranjan Locomotive Works (CLW) started operations in 1950, railway locomotives were fired by coal. The energy consumption pattern since then has changed. As have the fuel needs of the Indian Railways. From coal, CLW moved to electric locos and then to diesel-run ones.

With fuel getting costlier, the Indian Railways’ outfit started manufacturing energy-efficient three-phase locos about a decade ago, though initially it started with small numbers. Having completed 63 years of operations, CLW is now one of the largest electric locomotive makers in the world. During this journey, it has manufactured 15 types of locos.

Apart from serving the Railways, CLW has also contributed to the industrial growth of the Eastern region, and particularly West Bengal.

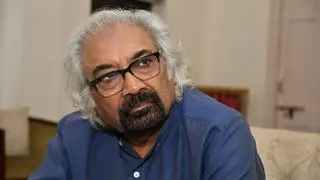

The locomotive maker will enter a new era, said Radhey Shyam, General Manager, CLW, once it changes the entire fleet to energy-efficient (three-phase) locos by 2015.

Currently, the Railways’ loco requirement is largely served by CLW. For 2013-14, it has been set a target of 275 locos, and CLW is confident of achieving it.

“We will definitely achieve this target. We can also surpass it depending on the availability of funds,” said Shyam.

To increase its production capacity, CLW is setting up an ancillary unit at Dankuni (Hooghly), about 220 km south-east of the existing facility at Chittaranjan. CLW expects to roll out the first three-phase loco from the Dankuni facility by the end of this fiscal.

“The ancillary unit at Dankuni, which is under construction, will have the capacity to manufacture 100 three-phase locomotives a year. We hope to turn out the first locomotive from Dankuni by the last quarter (Q4) of this fiscal,” said Shyam.

According to him, the Dankuni unit will entail an estimated investment of Rs 270 crore. It has tied up with a Japanese company for the technology to develop energy-efficient locos. Capable of hauling goods trains with more freight cars, these locos will also be used for the proposed dedicated freight corridors, said Shyam.

Upgrading capacity

CLW will also focus on upgrading its manufacturing facilities to meet the demand for energy-efficient locos.

“In 2012-13, we made 270 locomotives. While 160 of them were conventional ones, 110 were three-phase locomotives. Now the plan is to produce more three-phase locomotives,” said Shyam.

“By 2014-15, CLW aims to switch to three-phase locomotive manufacturing completely,” he added.

So far this year, CLW has manufactured 121 locos against 96 during the year-ago period and all the additional locomotives are of the energy efficient variety.

Indigenisation of components has also been a major focus area for CLW.

According to Shyam, CLW has brought down the use of imported components in the three-phase electric locos to under five per cent, resulting in substantial cost reduction. It will take necessary steps to further indigenise production, he said.

Modernisation

In the last fiscal, CLW rolled out 270 locos from Chittaranjan after its capacity was enhanced from 230 locos a year.

Equipment and capacities are being upgraded at Chittaranjan in the current Plan period in order to scale up the manufacturing capacity substantially and meet the increasing demand from the Railways.

The modernisation of its design and development centre, at an estimated investment of Rs 42 crore, is in full swing.

As part of the modernisation programme, it will develop a new centre for simulation and evaluation of suspension of bogie and traction system. These apart, a lab for loco software development, power electronics, electric loco modelling, and electrical insulation materials is planned.

CLW’s design and development centre will develop a technology called “hotel load converter” to supply power to the pantry car from the loco itself.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.