If there is one IKEA product that has achieved cult status, it is Blåhaj — a plush three feet long shark toy with a blue top coat and a soft white belly. People post cute videos of Blahaj parties on Tik Tok, and Reddit is filled with memes featuring the cuddly shark. Blahaj even made an appearance in the Marvel Studios’ Hawkeye.

Guess where Blahaj is manufactured? At a sprawling 25 acre textile factory in Ludhiana run by the Jawandsons group. Here, on a line, you watch a batch of the iconic blue sharks emerge, and then go in for a quality check to pass IKEA’s stringent standards.

The factory is a hive of enterprise. On different floors, woollen throws, blankets, toys, bibs, knitwear and sundry other products are manufactured, a bulk of it commissioned by IKEA. “Our journey with the Swedish retailer started in 2001 — we have done more than €40 million worth of business with IKEA,” says Gian Singh, the 37-year MD of Jawandsons group, and gen next in the family-owned business that started its journey in the 1970s.

After decades of exporting to big brands like IKEA, H&M, Zara, Australia’s Kmart and Japan’s Nitori, the next generation of the textile family is keen to knit a different story — create a strong domestic focussed nursery-care retail brand. In 2020, Gian along with his sister in law Gurnam Kaur (27) and cousin’s wife Preeti Chugh (37) started MiArcus with ambitions of becoming a one stop solution to all baby needs. In its third year, MiArcus has already scaled to 38 stores across the country and plans to hit 100 stores by 2025. Many of the products for MiArcus, especially the knitwear, baby blankets, throws and toys, come from the Jawandsons factory, though items like furniture are sourced from other suppliers and white-labelled.

On the same floor where the Ikea toys are produced, an eyecatching set of elephants in different shades — blue, cream and grey — are being sewn up. This is Stampy, the mascot of MiArcus. Each toy at MiArcus — which incidentally means my rainbow — has a name and a story.

Like many textile entrepreneurs in Punjab, the Singh family’s saga too started post partition when they migrated to India. In 1970, the Oster group (Jawandsons is part of it) run by Gian’s two uncles and his father started a small knitwear unit in Ludhiana. “They set up a small manufacturing unit for sweaters and mostly supplied to Russia, through government licences,” describes Singh.

In 1991 when the economy opened up and the group could deal directly with customers in Europe, the business grew in leaps and bounds. In 2001, at a textile exhibition in Germany, Oster met IKEA. The Swedish retailer was looking for a supplier for woollen throws. “They found us good. Today we are one of the biggest textile suppliers for IKEA from India, exporting to more than 40 countries for them. Wherever they have a store globally, we supply,” says Singh.

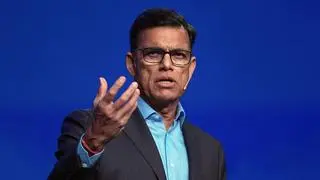

(From Left) Gian Singh, Founder and CEO, Gurnam Kaur, Co-founder and Retail Head, Preeti Chugh, Creative head

In 2014, the group decided to explore partnerships with other customers and signed up with a host of players like H&M, Zara, Nitori, a Japanese home furnishings major, Kmart, an Australian retailer, and set up a different factory for its non IKEA customers. In 2010, the group, which by now had three companies — Oster (for sweaters), Titlis (set up in 2002 for domestic home furnishings) and Jawandsons (set up in 2005 for exports) — split amicably, with the three brothers taking one business each. Gian’s father GB Singh got the Jawandsons business that supplied to IKEA.

In 2019, Gian, who had often been asked by his friends why the baby products they were exporting were not available in India, decided to take the plunge. Although there were players like First Cry and Baby Oye, he says, they felt they could supply European standard products at affordable prices, thanks to their formidable manufacturing strength. “The size of the babycare market in India is around ₹30,000 crore and there is a lot of headroom for growth,” he says.

He roped in Chugh, who incidentally is part of the Titlis group, as the creative head, and his sister-in-law Gurnam Kaur as the retail head. “When you are founding a company, you look for partners with different strengths. Preeti had done a course in designing while Gurnam had finished a course from in family business management,” says Gian. Both Gian and Gurnam also did a course in retail from ISB Mohali. Additionally, all three are parents of young kids and know the exact pain and pleasure points when it comes to baby needs. For instance, coming up is a lightweight stroller that can collapse at a touch and be carried up flights of stairs with a baby in arms.

They were ready to launch in 2020 but Covid struck. However, it also came as a boon — because they could sign store leases at an inexpensive rate. “Many brands were closing their stores and we got unbelievable rental deals in malls where otherwise as a new brand we would have found it tough to enter,” says Gurnam.

In three years they have invested roughly ₹26 crore in the business — a bulk of which goes in store rentals. Sales are clipping along, both online and offline, at ₹3.5 crore monthly, with winter months seeing a huge spike, given their knitwear inventory. “We are targeting ₹60 crore next year,” says Gian.

Wazir Consultants, who the trio hired, advised them to take stores of at least 800 sq ft area, and first focus on products, the company itself makes. A visit to the MiArcus store in Mohali shows an invitingly designed pastel paradise with a giant hoarding of brand ambassador Kareena Kapoor, a perfect fit as she is a hands-on mom. The trio has spent considerable time on marketing, starting with the brand name — MiArcus means my rainbow and denotes the colours of happiness that floods a home when a baby arrives. “We want to make parenthood joyful,” he says. Gurnam and Preeti say that when Kareena’s contract ends they want to sign on a celebrity couple with a small kid, with the father playing as important a role.

They are very gungho about the strength of ‘Make In India’. “We are hearing China plus One at many of the overseas exhibitions we go to, and this spurs us on,” says Gian. But the biggest kick he says is that they are getting export orders for toys to China — the place where everyone sources toys from.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.