New Delhi-based popular research organisation, The Energy and Resources Institute (TERI), has come up with a unique technology to treat industrial wastewater that will ensure affordable and sustainable Zero Liquid Discharge (ZLD) compliance set by the Central Pollution Control Board (CPCB) for Common Effluent Treatment Plants (CETP) in industrial clusters, said Dr Nupur Bahadur, Associate Director, TERI and Inventor of the technology .

In the first phase, the NMCG-TERI Centre of Excellence on Water Reuse, headed by Bahadur, has completed a pilot project to treat 20,000 litres per day (20 KLD) of effluent from the textile CETP in Rooma Industrial Area, Kanpur, Uttar Pradesh. The CEPT treats effluent discharge from 11 individual units. “This is the first of its kind demonstration in the World of UV-Photocatalysis based Advanced Oxidation Technology (TADOX®) for treatment of textile effluent in a CETP at this capacity,” said Bahadur.

Dr Nupur Bahadur, Associate Director, TERI and Inventor of TADOX technology

This should cheer up CETP clusters elsewhere in the country, particularly Tirupur, which is under scrutiny despite having CETPs and the Noyyal river in the district often seen “coloured”.

The technology is affordable since the treatment of effluents costs ₹175-200 against ₹300-450 under the current practice for treating 1,000 litres to achieve ZLD. “Again, the cost of the current system depends on the colour, shade and other such things,” said Bahadur.

Cuts key pollutants

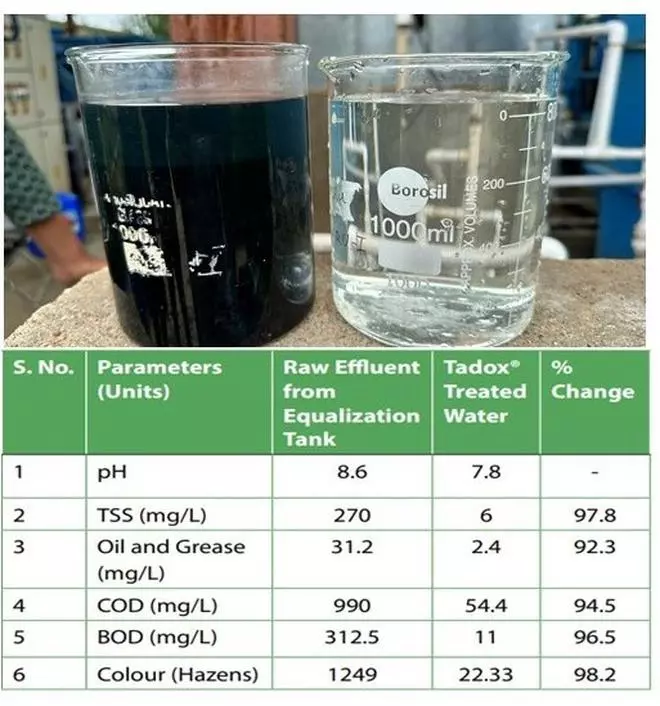

When treated with TADOX technology, the effluent turns colourless, with significant reductions in other key parameters, as depicted in table below. “This demonstrated exceptional operational resilience and reduced key pollutants by significant margins, ensuring compliance with strict environmental norms. By integrating TADOX® at the pre-biological treatment stage, the project aims to enhance biodegradability, reduce load on tertiary treatment, and achieve Zero Liquid Discharge (ZLD) in a sustainable and economically viable manner,” said Dr Bahadur.

The technology for which TERI has sought patent, remains same for treatment of other industrial effluents in a CEPT like textile, tannery, oil and grease, slaughterhouses, chemical, pesticides, pharmaceuticals etc. besides treating municipal and sewage wastewater. Also, it is a retrofittable and integrated solution as per the treatment requirement of different effluents based on their nature and composition”.

Water samples results before and after

Tackling sludge

Next is the huge amount of sludge, since a lot of chemicals are used in the wastewater treatment. “This creates a parallel problem, which is around 30-40 kg per cubic metre and toxic in nature. Transport costs are also involved in disposing them of,” she said.

“The innovation we have made is that we don’t use the chemicals that are the real culprits for the large amount of sludge. We use such formulations in primary treatment where sludge is reduced to 0.5 kg per metre cube and is also non-toxic, when tested on 88 parameters as per the Ministry guidelines. In the secondary stage, certain nanomaterials are added which treat the effluent in the presence of UV Light in a closed assembly, thus further reducing the use of chemicals in treatment,” said Bahadur.

Integration of solar PV

The 2015 notification for 17 highly polluting industries stipulates that wastewater will have to be treated to achieve quality for reusing it. “Existing ZLD solutions are not acceptable by industrial associations and clusters because they are highly resource and energy-intensive, besides leading to other problems. This is where we as scientists try to solve them through such advanced technology interventions” Bahadur said.

“We further suggest integration of renewable energy sources like the Solar PV along with TADOX Systems, which holds immense potential, not only for significantly reducing Global Warming Potential (GWP) but also for slashing operational expenses (OPEX) by further 40 per cent. Thus, we will be able to achieve net zero emission targets. We have recommended to the government to revise the ZLD guidelines as achieving the zero discharge is achievable,” said Bahadur.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.