When the owners and top management of leading domestic drug companies spend an entire day together, interacting with foreign and local regulators, the message is clear. Quality matters.

Or as one slide at the conclave put it quite simply: “Quality is doing the right thing when no one is looking: Henry Ford.”

The seriousness of this message was not lost on the room full of pharma industry representatives, since local drugmakers have been under intense regulatory scrutiny, particularly in the United States. Besides receiving warning letters, some even face import bans.

The highpoint of this day-long technical session by the Indian Pharmaceutical Alliance was the participation of officials from the United States Food and Drug Administration (USFDA), the European Medicines Agency, the United Kingdom’s Medicines & Healthcare products Regulatory Agency (MHRA) and the Drug Controller General of India. And listening rapt in the audience were Sun Pharma’s Dilip Shanghvi, Lupin’s Nilesh Gupta, Dr Reddy’s Satish Reddy and GV Prasad, Zydus Cadila’s Pankaj Patel, Torrent Pharma’s Samir Mehta and Cipla’s Subhanu Saxena.

Quality matters simply because it has all to do with patient safety, the regulatory officials said. But given the global landscape in which Indian drug companies operate, there is another battle out there.

The real battle for drug companies is not with regulators, but with competition from the region, said Thomas Cosgrove, USFDA’s Director (Office of Manufacturing Quality). Last year China’s drug regulator asked companies to undertake a voluntary audit of all pending drug applications, following which many were withdrawn, he said. (Reports suggest 50 to 80 per cent were withdrawn).

This showed two things: that there was a significant problem that needed to be fixed. And the Chinese regulator was serious about fixing that problem, he told an attentive audience.

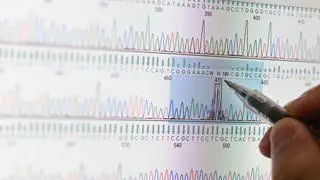

Data and its integrityGetting the quality benchmark right involved the submission of “complete, consistent and accurate data” by companies to the regulator. But companies often fell foul of this requirement on documentation of data, tests, processes, etc.

Data integrity underpins good manufacturing practices and lapses indicate that other problems are obscured, further concealing the risk to patients, explained Cosgrove.

Such lapses ring alarm bells for the regulator as it is the tip of the iceberg, he said. A Mckinsey report unveiled at the meet said that 10 of the 19 quality-related warning letters issued globally in 2014 had data reliability issues. A pattern that continued in 2015 (up to August), where nine out of 10 showed red flags on data.

Transgressions by drug companies included, lack of controlled access to data, deleting and backdating of data, fabricating data, etc.

The McKinsey report, however, observed that firms were bringing in improvements, including accurate data recording, access controls for sensitive data (eliminating common logins) etc.

Walk the talkBut all this quality talk has to be driven by top management. Gerald Heddell, MHRA’s Director Inspection, Enforcements and Standards Division, urged companies to reward staff for “telling you bad news”. Encourage people to blow the whistle, he said.

Sometimes your “strength” can be the “downfall” too, he observed, referring to how respect for authority (parents, teachers) can become a weakness in a company where employees don’t speak up

Cosgrove added that fixing responsibility when something went wrong should not involve “scape-goating” of a junior person. It may come as small consolation that the regulators’ also said that quality was not solely an Indian problem. It was as much a concern in the US and Europe. But as one industry chief said, it was in the local industry’s best interests to clean up its act, and quickly.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.